When it comes to securing, lifting, or anchoring objects, choosing the right hardware is essential for safety and durability. Brass eyebolts are a popular choice among DIY enthusiasts and professionals alike, known for their resistance to corrosion, strength, and aesthetic appeal. Whether you’re working on a home improvement project, crafting, or engaging in heavy-duty lifting applications, understanding the features of the best brass eyebolts can make all the difference. This comprehensive guide will help you navigate the options available and find the perfect eyebolts to suit your needs.

In this article, we will explore the top-rated brass eyebolts on the market, providing in-depth reviews and insights into their specifications, uses, and advantages. We’ll also offer a buying guide that highlights crucial factors to consider, ensuring you make an informed decision. Dive into the world of brass eyebolts with us and discover how these versatile fasteners can elevate your projects and enhance their overall performance.

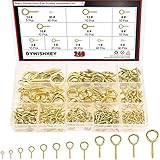

Before moving into the reviews of the best brass eyebolts, let’s check out some of the relevant products from Amazon:

Last update on 2026-01-19 at 16:14 / Paid links / Images from Amazon Product Advertising API

Overview of Brass Eyebolts

Brass eyebolts are essential hardware components often utilized in various applications, from marine settings to household fixtures. Made from a copper-zinc alloy, brass is known for its corrosion resistance, making it a preferred choice in environments that may involve moisture or saltwater exposure. Their superior durability and strength make brass eyebolts suitable for securing objects, rigging, and lifting operations, ensuring safety and reliability in their usage.

The design of brass eyebolts typically features a threaded shaft and a loop or ring at the top, allowing for easy attachment of ropes, cables, or other fastening materials. This design provides a versatile solution for mounting, hanging, or securing items. Depending on the specific model and manufacturer, they come in various sizes and load capacities, catering to different needs and ensuring optimal performance in any task where strength is paramount.

In addition to their structural integrity, brass eyebolts also bring aesthetic value. The warm, golden hue of brass can enhance the visual appeal of projects, especially when used in decorative applications. This characteristic makes them popular not only for practical uses but also for artistic and architectural design elements, where appearance and function must coexist harmoniously.

When searching for the best brass eyebolts, it’s crucial to consider factors such as the load rating, size, and application. Top manufacturers provide high-quality products that meet rigorous industry standards, ensuring that users receive reliable and durable eyebolts for their specific needs. By choosing the right brass eyebolts, one can ensure safety, functionality, and an appealing look for both practical and decorative purposes.

Best Brass Eyebolts – Reviews

1. Miavogo Brass Eyebolts

Miavogo’s brass eyebolts are a standout option for heavy-duty applications, ensuring durability and reliability. Crafted from high-quality brass, these eyebolts exhibit excellent resistance to corrosion, making them ideal for both indoor and outdoor use. The solid construction is designed to withstand substantial loads, making them perfect for securing various items, from home decor to outdoor equipment.

Users appreciate the ease of installation, with a smooth threading that accommodates various nuts and washers. The polished finish not only enhances aesthetic appeal but also provides a smooth surface that reduces the risk of injury during handling. Overall, Miavogo brass eyebolts combine functionality with style, perfect for those who seek both strong performance and visual elegance.

2. National Mfg. N200-869 Brass Eyebolts

The National Mfg. N200-869 brass eyebolts are engineered for reliability and strength. With a maximum working load limit that suits a wide range of applications, these eyebolts are particularly favored for marine and outdoor settings due to their resistance to rust and other environmental factors. The quality of craftsmanship is evident with each unit, ensuring consistent performance over time.

Installation is a breeze with these eyebolts, as their design accommodates quick setup without compromising safety. Users note the solid grip that provides security when fastening, giving peace of mind whether they’re used in boating, construction, or home projects. The blend of functionality and weather resistance makes the National Mfg. eyebolts a trusted choice among professionals and DIY enthusiasts alike.

3. Crown Bolt 70256 Brass Eyebolts

Crown Bolt’s 70256 brass eyebolts are a reliable choice when seeking both quality and affordability. Their brass material provides a strong resistance to corrosion, making them suitable for both marine and freshwater environments. With a dependable load capacity, these eyebolts can be effectively utilized in various settings, ranging from home repairs to hobby projects.

Reviewers have consistently praised the eyebolts for their smooth finish and ease of handling, which reduces the risk of snagging or cutting when working on projects. Additionally, their straightforward design simplifies installation, making them accessible for users of all skill levels. Crown Bolt successfully delivers a product that meets both functional needs and budget-friendly expectations.

4. Hillman Group 844395 Brass Eyebolts

The Hillman Group 844395 brass eyebolts offer a solid construction that ensures they can handle significant weight and tension with ease. Designed for various applications, these eyebolts are made from premium brass, which not only contributes to their strength but also provides excellent corrosion resistance. This makes them a perfect candidate for outdoor uses, where exposure to the elements can compromise lesser materials.

Feedback from users highlights the reliable performance of Hillman eyebolts, with many noting their effectiveness in securing childhood swings, garden decor, and other fixtures. The installation process is straightforward, with clear instructions that allow users to achieve a tight and secure fit. Overall, these eyebolts provide a balance of strength, reliability, and ease of use that makes them a popular choice for many individuals and professionals.

5. FastenMaster 94219 Brass Eyebolts

FastenMaster’s 94219 brass eyebolts stand out for their robust design and versatile usage. Engineered for both strength and aesthetic appeal, these eyebolts come in a polished finish that resists tarnishing. Their sturdy build is perfect for projects that demand a mixture of style and strength, such as home improvement tasks or crafted decor.

Users are particularly pleased with the ease of installation and the versatility these eyebolts provide. Whether securing furniture, hanging artwork, or crafting outdoor installations, the FastenMaster eyebolts deliver strong performance across a range of applications. Their quality construction and beautiful finish make them a well-rounded option for both DIYers and professionals looking for dependability and visual charm.

Why People Need to Buy Brass Eyebolts

Brass eyebolts are essential hardware components that serve numerous practical purposes both in everyday and specialized applications. Their durable construction and resistance to corrosion make them ideal for outdoor and marine environments, fulfilling the need for strong and reliable fastening solutions. Whether for securing equipment, suspending items, or creating anchor points, brass eyebolts provide a versatile solution that can adapt to various needs and settings.

One of the significant advantages of brass eyebolts is their aesthetic appeal. Unlike their steel counterparts, which can rust and deteriorate over time, brass retains its luster and presents a polished appearance. This quality makes them not only functional but also an attractive option for decorative projects where visual appeal is just as important as practicality. The golden hue of brass often complements a wide range of materials and colors, making it a preferred choice for artisans and DIY enthusiasts alike.

In addition to aesthetics, brass eyebolts are known for their exceptional strength and load-bearing capabilities. They can withstand significant weight and stress, making them suitable for heavy-duty applications such as rigging, marine installations, and structural supports. When selecting the best brass eyebolts, consumers can find various sizes and load ratings to match their specific requirements, ensuring optimal performance in their chosen applications.

Lastly, investing in high-quality brass eyebolts contributes to long-term cost savings. Their durability translates into a lower frequency of replacement and repair, making them a wise choice for both commercial and personal projects. By choosing brass eyebolts, users can count on reliable performance, minimal maintenance, and enhanced safety, ultimately making their purchase a practical and beneficial one.

Features to Look for in Brass Eyebolts

When selecting brass eyebolts, it’s essential to consider several key features that ensure the product meets your specific needs. One primary aspect is the load capacity, as eyebolts are often used for lifting or securing objects. It’s vital to choose a product rated for the weight you intend to work with, as this impacts safety and functionality. Always check the manufacturer’s specifications for the maximum load capacity.

Another important feature is the thread type and length. The right thread ensures a secure fit, reducing the likelihood of slippage or failure under load. Varying thread designs, such as coarse or fine threads, serve different purposes and environments. Choose an eybolt with a length suitable for your application, allowing for the secure attachment of cables, ropes, or chains.

Lastly, consider the finish and corrosion resistance of the brass eyebolt. While brass offers natural resistance to corrosion, additional coatings can enhance protection in harsh environments. Features like a polished finish not only improve aesthetics but also can help in resisting tarnishing. By paying attention to these features, users can make informed decisions for their projects.

Common Applications of Brass Eyebolts

Brass eyebolts are versatile tools used in various applications across different industries. One common use is in marine environments, where they are essential for securing sails, rigging, or other gear on boats. Their corrosion resistance makes brass eyebolts particularly well-suited for applications exposed to saltwater. Sailboat owners often rely on these eyebolts for ensuring safety and structural integrity while navigating in unpredictable conditions.

In construction and woodworking, brass eyebolts are frequently used to provide secure attachment points for cables, wires, and other applications requiring load-bearing capabilities. Builders appreciate the durability and strength brass offers, making it a preferred choice when safety and reliability are paramount. Whether used for hoisting materials or as part of a structural framework, brass eyebolts can facilitate various tasks effectively.

Another area where brass eyebolts shine is in ornamental applications. Many artisans and craftsmen utilize these eyebolts in their designs, as they add a touch of elegance and sophistication to the finished product. From creating custom jewelry to decorative home furnishings, brass eyebolts elevate the aesthetic value, ensuring that practicality does not compromise visual appeal.

Maintenance and Care for Brass Eyebolts

To ensure the longevity and optimal performance of brass eyebolts, routine maintenance and care are crucial. One of the key practices involves regular cleaning to remove dirt, grease, and corrosion buildup. A simple solution of warm, soapy water with a gentle scrub can help maintain their shine and functionality. Make sure to dry the eyebolts thoroughly to prevent moisture accumulation, which could lead to tarnishing over time.

Occasional polishing is another excellent way to keep brass eyebolts looking their best. Use a brass polish and a soft cloth to gently buff the surface. This process not only enhances the appearance but also provides a protective layer that reduces tarnishing, prolonging the eyebolts’ life. It’s advisable to avoid harsh chemicals that might damage the brass finish or compromise its structural integrity.

Additionally, inspect your brass eyebolts periodically for signs of wear, such as cracks or deformities. Regular inspections can prevent accidents and failures by ensuring that eyebolts perform safely under load. If any damage is observed, replace the eyebolts immediately, as safety should always be the top priority in any application where they are utilized.

Comparison of Brass Eyebolts with Other Materials

When choosing eyebolts for your project, it’s important to compare brass with other materials, such as stainless steel, aluminum, or plastic. Brass eyebolts are favored for their aesthetic appeal and corrosion resistance, making them ideal for applications exposed to moisture. The classic golden hue of brass also adds a touch of elegance to visible hardware, which is particularly beneficial in decorative applications.

Stainless steel eyebolts, while stronger and more resistant to abrasion, often lack the aesthetic qualities of brass. They are excellent for heavy-duty applications that require superior strength and resistance to extreme weather conditions. However, their more utilitarian appearance may not suit projects where visual appeal is essential. When comparing the two, consider your primary focus: aesthetic versus strength.

Aluminum eyebolts are lighter than both brass and stainless steel, making them suitable for projects where weight is a concern. They are less prone to corrosion but typically do not support as high a load as brass or stainless steel. Plastic eyebolts may be appropriate for light-duty tasks and specific applications, such as when working with sensitive materials that could be scratched or damaged by metal. Ultimately, the choice between brass and other materials depends on the specific requirements of the application, including load capacity, environmental factors, and aesthetic preferences.

Buying Guide for the Best Brass Eyebolts

When searching for the best brass eyebolts, it’s essential to understand the features and specifications that align with your needs. Brass eyebolts are versatile hardware items widely used in applications ranging from construction to arts and crafts. This guide will delve into six critical factors to consider before making your purchase, ensuring you choose the right product for your specific requirements.

1. Load Capacity

One of the most crucial factors to consider when purchasing brass eyebolts is their load capacity. Different eyebolts are rated for varying levels of weight they can handle safely. Before making a selection, assess how much weight you need the eyebolt to support, as exceeding the weight limit can lead to failure and potentially dangerous situations.

Check the manufacturer’s specifications for load ratings, which are typically provided in pounds or kilograms. It’s advisable to choose eyebolts with a higher load capacity than you think you will need, allowing an added safety margin for unexpected stresses. This can be especially important in applications such as rigging or suspending heavy objects.

2. Size and Dimensions

Brass eyebolts come in various sizes, and selecting the right dimensions is vital for ensuring a proper fit and functionality within your specific project. Consider the diameter of the eyebolt, as this will affect both the load-bearing capacity and the ease of use in connecting cables or ropes.

Additionally, look at the length and threading of the eyebolt. The length needed will depend on the thickness of the material you are attaching it to, while the threading is crucial if you plan to screw the eyebolt into wood or other surfaces. Taking accurate measurements before purchasing can save you from inconveniences during installation.

3. Material Quality

While this guide focuses on brass eyebolts, not all brasses are created equal. The quality of the brass used can significantly impact the robustness and durability of the eyebolts. High-quality brass is resistant to corrosion, providing more extended use, especially in moist or saline environments.

When selecting eyebolts, check for details regarding the brass grade used in the manufacturing process. Premium grades typically ensure better performance in terms of strength and longevity. Some products may even be coated to enhance their resistance to environmental factors, providing additional value in your purchase.

4. Thread Type

The thread type of brass eyebolts can influence compatibility with your existing hardware. Eyebolts commonly feature either coarse or fine threads, and matching these with the nuts or screws you’re using will ensure a secure connection. It’s important to note that coarse threads generally provide better grip, while fine threads may facilitate easier adjustment and enable finer control.

When purchasing eyebolts, consider the specific applications where they will be used. A standard coarse thread is often used in general construction or heavy loads, whereas fine threads may be preferred in settings that require precise adjustments, such as in delicate rigging.

5. Finish and Coating

The finish and coating of brass eyebolts play a pivotal role in their aesthetic appeal and protection against corrosion or wear. A well-finished eyebolt not only has visual appeal but also enhances lifespan, especially in outdoor or humid conditions. Look for eyebolts with a polished or coated finish for increased resistance to tarnishing and corrosion.

Some manufacturers offer additional coatings, such as chrome or zinc, further enhancing the lifespan of the product by providing an extra barrier against environmental damage. When selecting among different finishes, consider where the eyebolts will be used and the look you want to achieve.

6. Price and Value

Budget is always a substantial factor when making a purchase, but when it comes to selecting the best brass eyebolts, it’s essential to also consider value. While you may find cheaper options, investing in higher-quality eyebolts may save you money in the long run by reducing the need for replacements.

Evaluate various pricing options while considering the quality and specifications of each product. Reading reviews and comparisons can help you understand the value offered by different brands and models. Remember, finding the right balance between cost and quality is key to ensuring that you make a sensible investment for your projects.

Frequently Asked Questions

What are brass eyebolts used for?

Brass eyebolts are versatile fasteners often used for anchoring or securing objects. Their robust design makes them ideal for both industrial and recreational applications, including marine usages, where corrosion resistance is critical. Commonly, they serve in situations requiring a connection point for a rope or cable, offering a reliable means to tether items for safety or support.

Additionally, brass material provides an aesthetic appeal alongside functionality. They are frequently utilized in furniture assembly, decorative fixtures, and various DIY projects. Due to the longevity and durability of brass, these eyebolts are also an excellent choice for outdoor applications where exposure to the elements is expected.

How do I choose the right size of brass eyebolt?

Choosing the right size of brass eyebolt involves assessing both the load requirements and the available space for installation. Eyebolts come in various sizes, so it’s essential to determine the weight of the object you intend to secure. Manufacturers often provide load ratings, and selecting an eyebolt that matches or exceeds the required strength ensures safe usage without risk of failure.

Moreover, consider the installation area and the orientation of the eyebolt. Ensure that you have adequate clearance around the installed eyebolt for easy access while using it. Take into account factors such as the thickness of the material you’ll be attaching it to and whether a through-hole or surface mount will be required, which can influence your size choice.

Are brass eyebolts corrosion-resistant?

Yes, brass eyebolts are known for their corrosion resistance, which is one of their most significant advantages. Brass is an alloy primarily made of copper and zinc, which provides durability and resistance to rust and tarnish, making it suitable for many environments, including marine settings. This property ensures that eyebolts maintain their structural integrity over time, even when exposed to moisture and salt.

However, while brass resists corrosion, it’s essential to choose high-quality brass eyebolts for the best performance. Lower-grade alloys may not perform as well in corrosive environments. Additionally, proper maintenance, such as cleaning and drying after exposure to saltwater, can extend the lifespan and functionality of brass eyebolts even further.

Can brass eyebolts be used in load-bearing applications?

Brass eyebolts can indeed be used in load-bearing applications, but there are important considerations to ensure safety and reliability. Always check the manufacturer’s load rating to confirm that the eyebolt can withstand the weight and forces it will encounter. For critical load-bearing applications, it’s advisable to factor in a safety margin to account for dynamic forces that may apply.

It’s also essential to install the eyebolts correctly to ensure they function safely under load. This includes using the appropriate mounting method, ensuring they are fully threaded into the material, and confirming they are not cross-threaded. Proper load distribution and positioning can significantly affect the integrity of the assembly.

Why is the material of the eyebolt important?

The material of an eyebolt is crucial because it directly affects the strength, durability, and suitability for specific environments. Brass is often favored for its corrosion resistance, particularly in humid or salty conditions. When selecting eyebolts, considering the environmental factors they will encounter ensures long-term performance and safety. Different materials, such as stainless steel or plastic, also have unique attributes and applications they cater to.

Furthermore, the material impacts the load-bearing capacity and compatibility with other hardware. Using mismatched materials can lead to corrosion issues or mechanical failure due to differing expansion rates or load characteristics. Choosing an eyebolt made from a suitable material for your intended application enhances the overall effectiveness and longevity of your connection point.

Are there any safety precautions to take when using brass eyebolts?

Yes, there are several safety precautions to consider when using brass eyebolts to ensure safe handling and prevent accidents. First, confirm the load capacity of the eyebolt and avoid exceeding it. This will help prevent potential failure and the associated risks. Using washers and securing nuts appropriately can provide additional stability and safety during use.

Additionally, inspect eyebolts regularly for signs of wear, corrosion, or damage, as these issues can compromise their integrity. Properly assess the installation methods used, ensuring that they are compliant with the intended use. Regular maintenance and attention to safety can significantly reduce the chances of accidents and ensure the brass eyebolts perform effectively over time.

How do I install a brass eyebolt?

Installing a brass eyebolt involves a few key steps to ensure it is secure and functions properly. Begin by selecting the appropriate size and type of eyebolt for your specific application. Then, prepare the installation surface, ensuring it is clean and free of debris. Mark the desired location for the eyebolt, making sure to account for the necessary clearance around it.

Next, drill a hole suitable for the eyebolt’s diameter if it’s a through-hole installation. If using a threaded eyebolt, ensure the threads engage fully. Insert the eyebolt and tighten it securely with a wrench, taking care not to over-tighten, which could damage the material or the eyebolt itself. Finally, test the installation by applying light tension to ensure it’s stable and ready for use.

Final Words

In conclusion, investing in the best brass eyebolts is a decision that enhances both functionality and durability in various applications. Their resistance to corrosion and robust construction make them ideal for both indoor and outdoor use, ensuring that they maintain their integrity over time. By selecting from the top-rated options we’ve discussed, you can trust that you are equipping yourself with reliable hardware that meets your specific needs, whether for home improvement projects, marine applications, or general construction.

Moreover, understanding the features, load capacities, and installation requirements of brass eyebolts allows you to make an informed choice that prioritizes safety and efficiency. By carefully considering the reviews and recommendations outlined in this guide, you can confidently select the best brass eyebolts for your next project, knowing that you have the highest standard of quality and performance at your disposal. Don’t compromise on safety and reliability; invest in top-quality brass eyebolts today.